Call us

Various

Laser Engarving |

Simulation |

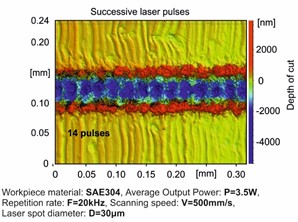

T he basic principle of the laser engraving process is that through laser beam pulses, a large amount of heat is imparted locally into the material of the workpiece that must be removed in order to cause its sublimation. Laser engraving process is based on the laser ablation process of the materials. During the laser ablation process a laser beam pulse hits the surface of the workpiece material, providing a large amount of focused heat energy first causing melting, then vapourization-ablation and finally the removal of ablated target material in the form of vapour. When a sequence of continuous laser beam pulses is scanned over the workpiece, the overall ablated material that is removed produces a 3D geometry with a specific thickness, which is called a single pass removed layer. By making multiple passes with a predefined geometry on each layer, 3D geometries are able to be engraved over the workpiece.

|

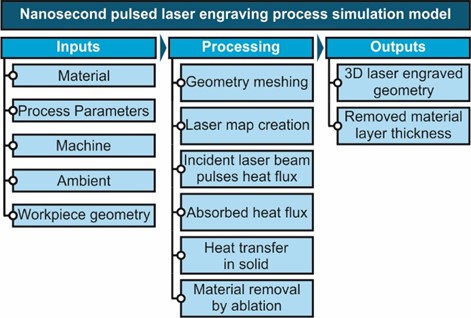

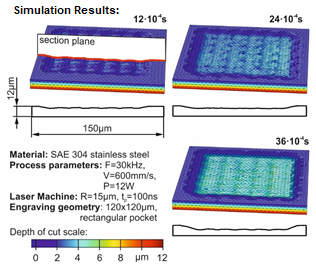

A 3D simulation model for nanosecond pulsed laser engraving process is developed, using the Finite Element Method (FEM) aiming at the prediction of the final geometry of the workpiece and optimizing the process. The development of a precise and reliable simulation model is particularly important as it will enable the ability to study the effect of material properties and the process parameters on dimensional accuracy, manufacturing quality and machining time.

|

Simulation test results for the case of engraving a 0.12x0.12mm rectangular pocket with F=30kHz, V=600mm/s, P=12W laser process parameters. |

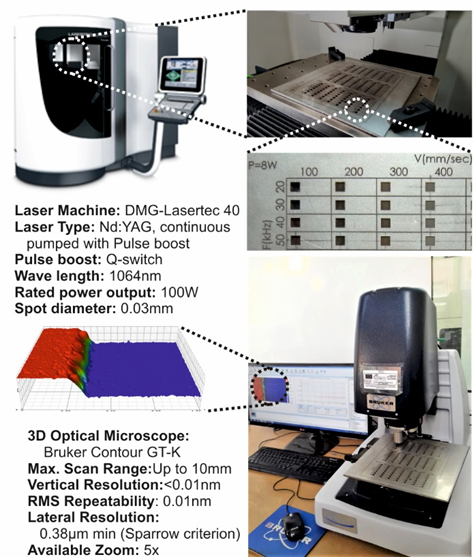

In order to verify the simulation model a large set of experiments was performed for the purpose of comparing the experimental with the simulation results. For this purpose, laser engraving process experimental samples were conducted using a DMG MORI Lasertec 40 machine for some widely used materials using a wide range of process parameters.

|

Your contact:

|