Call us

Equipment

DMU 50 eco

Machining Center (3+2) axes

The DMU 50 eco is a cost-effective 5-axis machining center featuring a swivel rotary table (B-axis: -5° to +110°, C-axis: 360°), an 8,000 rpm spindle, and a 16-tool magazine. Designed for flexible and precise machining, it offers high performance and efficiency, reducing overall production time.

Read moreCTX 310 eco

Turning Center (2) axes

The CTX 301 eco is a precision turning center with a 12-station turret, Siemens 840D SL control, and a 16 kW / 5,000 rpm spindle. It features digital drives, linear guideways, and automatic tailstock for high accuracy and flexible machining.

Read moreLASERTEC 40

Laser engraving (3+2) axes

The LASERTEC 40 series enables high-quality 3D laser engraving and machining of fine contours without tool wear, offering faster cycles, higher precision, and reproducibility.

Read moreThe UNO series is ideal for standalone and entry-level tool measurement up to ø230 mm and 370 mm length, featuring a durable cast-iron base and fast Edge-Finder positioning.

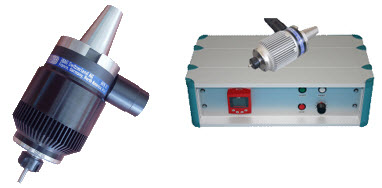

Read moreIBAG HFK 95

High Speed Spindle

The “Plug & Go” spindles allow quick installation on horizontal or vertical machining centers, enabling high-speed conversion in under five seconds. The HFK 95, the smallest model, is lightweight, air-cooled, and compatible with automatic tool changers.

Read moreBruker Contour GT-K 3D

Optical Profilometer

The ContourGT-K 3D Optical Microscope sets a new industry standard in design and cost for surface metrology performance

Read moreMitutoyo M574

Coordinate Measuring Machine

CRYSTA-PLUS M is the intelligent alternative to the complex, cost-intensive measuring equipment with conventional multi-point measuring devices

Read moreKISTLER 9257

Multicomponent dynamometer

Quartz dynamometer for measuring the three orthogonal components of a force

Read moreKISTLER 9256C2

Microdynamometer

Quartz micro dynamometer for measuring the three orthogonal components of a force.

Read moreMotionBLITZ

Highspeed Camera

The MotionBLITZ EoSens® mini2 meets the requirements of the most varied applications, because resolution and speed can be user defined as needed

Read moreHeidenhain TS 642

Touching probe

The TS 642 shares the essential electrical and mechanical properties of the TS 640

Read more